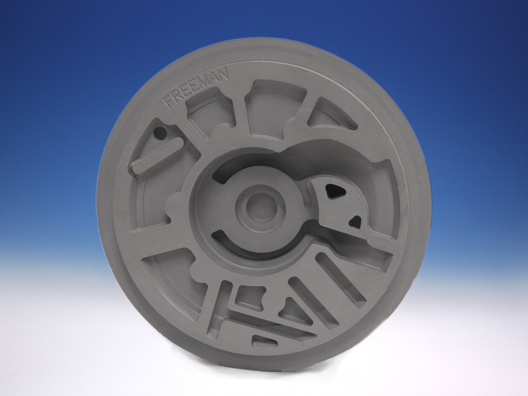

Aluminum-Filled Room Temperature Resins

Aluminum-filled epoxy casting resins (gray in color) are not as heavy as iron-filled systems and are more readily machinable.

Epoxy casting resins generate heat (exotherm) during the curing process. This heat can become excessive if the epoxy is poured thicker than the suggested casting thickness, causing warping, cracking and/or brittleness. Therefore, be careful to choose the correct system for your project.

Epoxy casting resins generate heat (exotherm) during the curing process. This heat can become excessive if the epoxy is poured thicker than the suggested casting thickness, causing warping, cracking and/or brittleness. Therefore, be careful to choose the correct system for your project.

Freeman 805 Aluminum-Filled Epoxy Casting Resin

88D Shore Hardness / 1/2" Cast Thickness / 150 Min. Gel Time

SikaBiresin G410 Aluminum-Filled Epoxy Surface / Mass Casting Resin

84 Shore Hardness / Up to 4" Cast Thickness / 100 Min. Gel Time

Freeman 821 Aluminum-Filled Epoxy Casting Resin

83D Shore Hardness / 4" Cast Thickness / 85 Min. Gel Time

Devcon Epoxy Plastic Aluminum - Liquid

85D Shore Hardness / 1" Cast Thickness / 45 Min. Gel Time