Epoxy Casting Resins

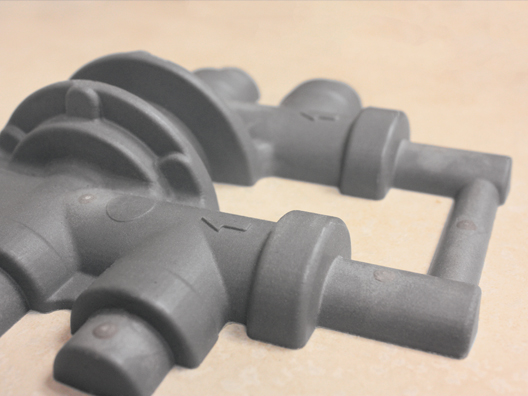

Freeman offers a broad, diverse line of pourable epoxy casting resins for the production of foundry patterns, core boxes, molds, fixtures, and tooling.

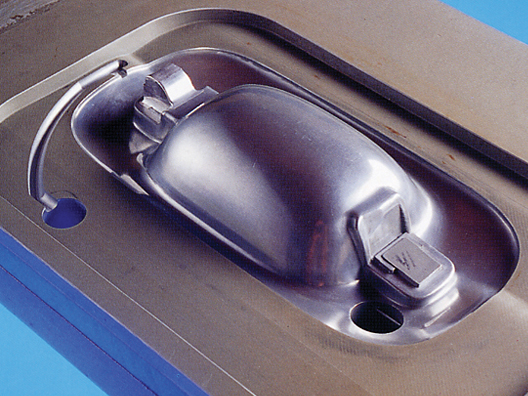

Aluminum-filled epoxy casting resins (gray in color) are not as heavy, are more readily machinable, and are available with higher temperature resistances.

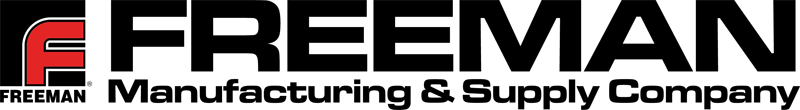

Iron-filled epoxy casting resins (black in color) are heavy, highly wear-resistant compounds that are suitable for foundry patterns or thin-gauge metal-forming tools.

Aluminum-filled epoxy casting resins (gray in color) are not as heavy, are more readily machinable, and are available with higher temperature resistances.

Iron-filled epoxy casting resins (black in color) are heavy, highly wear-resistant compounds that are suitable for foundry patterns or thin-gauge metal-forming tools.

Aluminum-Filled Room Temperature Resins

Generally lighter and easier to machine than iron-filled epoxies

Aluminum-Filled High Temperature Resins

High-temperature resistances ranging from 225°F-300°F

Iron-Filled Epoxy Casting Resins

High-impact strength

Other Epoxy Casting Resins

Clear & Steel Filled Epoxy Options

Discontinued Epoxy Casting Resins

Informational pages for discontinued items. Some stock may still be available.